IQUBX Dry wall cladding room partition is a combination of two widely used techniques or systems,

- Stone Dry cladding Technique

- Dry wall construction framework with board cladding like gypsum board

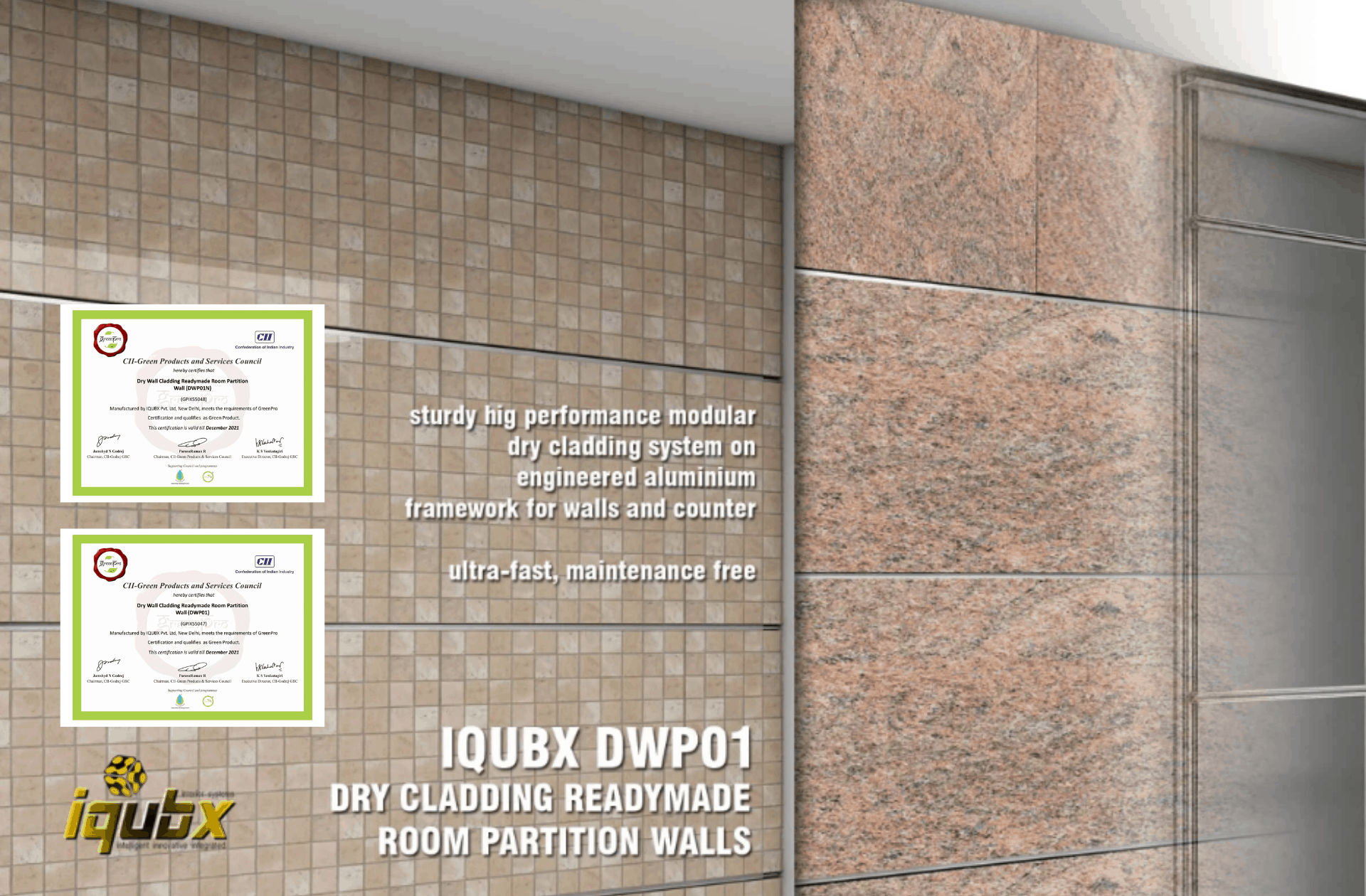

Through this combination a new modular system is evolved which is completely dry ready-made partition system with cladding of stone or tile.

iqubx dry cladding readmade walls

Dry wall partition

Typically, Dry wall is made up with gypsum board or plaster board & calcium silicate boards. As per Wikipedia Drywall (also known as plasterboard, wallboard, sheet rock, gyp-rock, gypsum board, or gypsum panel) is a panel made of calcium sulfate dehydrate (gypsum), with or without additives, typically extruded between thick sheets of facer and backer paper, used in the construction of interior walls and ceilings.

Download “Iqubx demountable partition & paneling, stone & tile cladding dry wall partitions apr22” iqubx-demountable-paneling-dry-wall-partitions-apr22.pdf – Downloaded 11479 times – 9.13 MBIQUBX Dry Wall Cladding Readymade Room Partition Wall DWP01

This unique ready-made room partition wall is, in a way, a high performance modular prefabricated wall with stone, tile cladding or paint finish & replaces traditional masonry brick or block walls in a building. This modular system has several advantages over traditional masonry, including, far less labour cost, ease and speed of installation, superior finish & detail, re-usability.

With use of this system, overall weight of the building is reduced as well as structure cost.

One of the best advantages of this modular dry cladding system is the ease of post-construction access to embedded services like plumbing, electric and HVAC etc, due to removable finishing panels.

These partitions can be acoustically treated also to create a very safe & quite environment.

Labor cost is minimized & a very short construction time with high quality detailing & finish can be achieved. This kind of dry wall technique can also provide flexibility for future changes to the layouts.

This Drywall cladding room partition system is highly recommended for interior & exterior walls with maintenance free installation.

iqubx_dry_cladding_readymade_room_partition_wall_construction

Construction of Dry Wall Cladding Room Partition

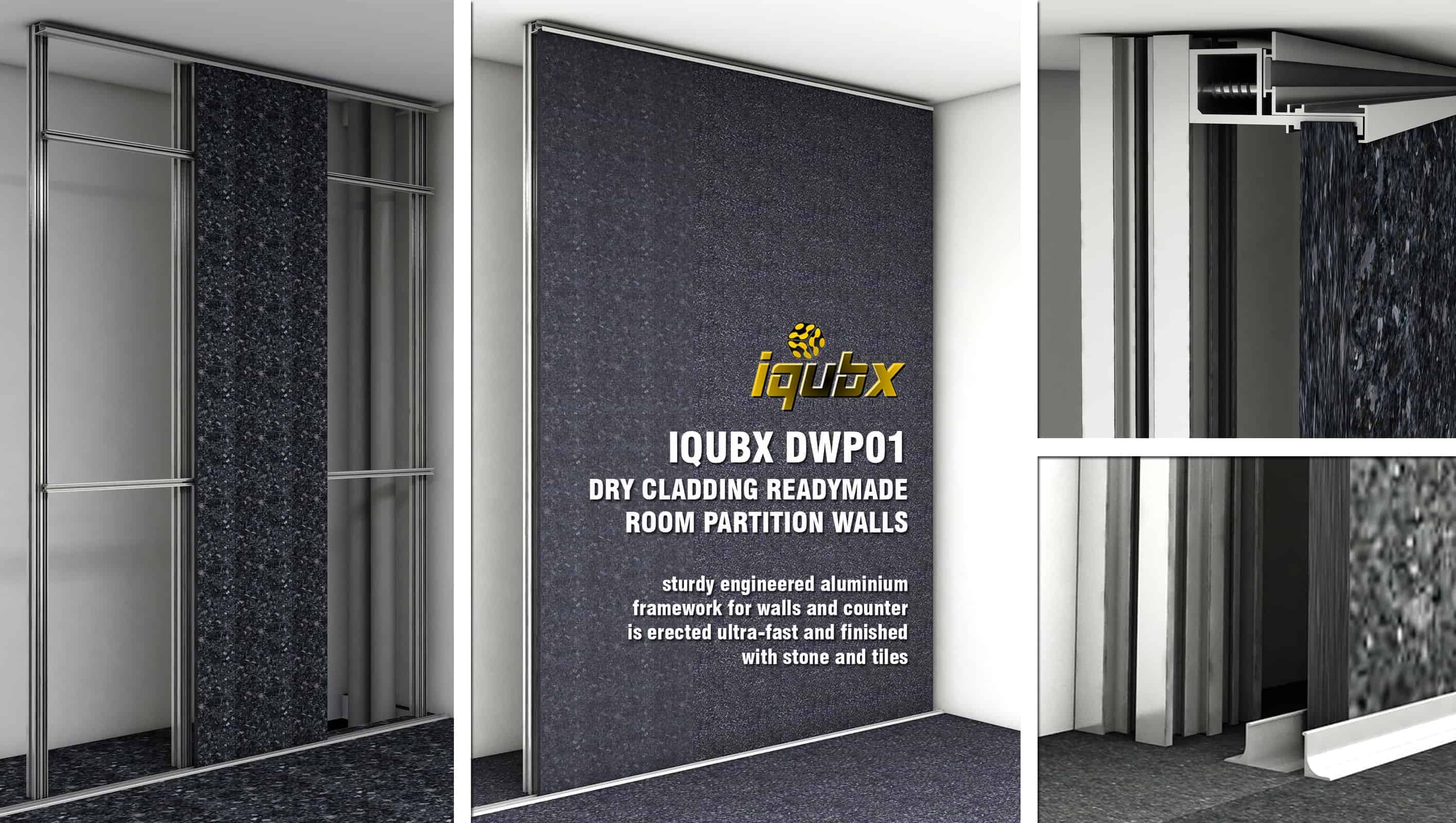

This modular system is made of Aluminium engineered sections with high tensile & bending moment strength, and functionality of modular joinery with Allen bolts & nuts as well as screws.

This modular post & real frame is the main stay or the backbone of the dry wall partition.

On this frame, services can be supported depending on area of use. For instance, in wet areas, plumbing pipes can be tied to the internal structure aluminium members. They can be further supported with the help of aluminium sheets fix to the frame.

iqubx_dry_cladding_readymade_room_partition_wall

Notably, Aluminium, a green building material, is very good choice for dry walls especially in wet areas, because of it’s inherent advantage of being non corrosive, non rusting and weather or element proof, while being strong, durable & very light. Therefore the weight of the entire building is reduced by use of IQUBX Dry Wall Cladding Readymade Room Partition system.

Download “Iqubx demountable partition & paneling, stone & tile cladding dry wall partitions apr22” iqubx-demountable-paneling-dry-wall-partitions-apr22.pdf – Downloaded 11479 times – 9.13 MBSubsequently, the Finishing panel of stone, tile or may be block board are positioned in the base channel which is fixed to the floor. This base channel has built-in skirting on both sides which gives an Aesthetic junction to the wall with floor. It also allows water proofing of the joint of the wall and the floor with silicon.

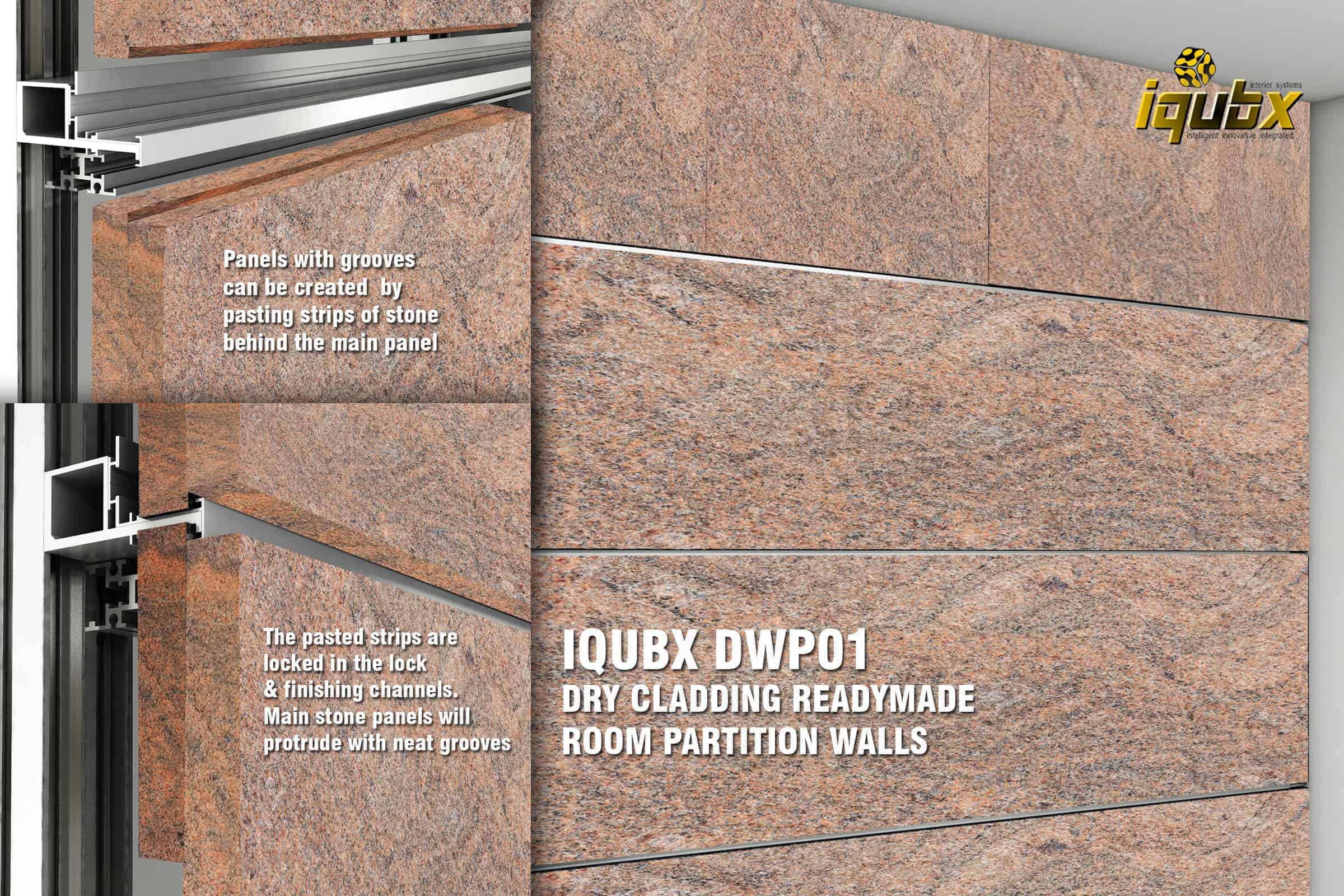

After this, the panels are positioned in plumb and line and the locking channel for individual panels is fixed at the top.

After finishing the installation of all the panels, the finishing top channel is fixed at the top. There is also possibility of giving bands of different material or color in the center in the system as well as to achieve grooves in tiles/stone panels.

iqubx_dry_cladding_readymade_room_partition_wall

Applications

IQUBX dry stone cladding ready made room partition walls can be used to partition any interior. They find application in almost all kind of projects including offices, homes, hospitality projects like hotels, banquet halls, malls, hospitals, Institutions like schools and colleges as well as industry & any other project where high quality finish and time is valued.

This dry ready-made walls can be used in wet areas like kitchens and toilets as well as dry areas like rooms and halls. Being modular in nature they can be installed and removed easily, therefore, they are ideal for temporary extension structures. The same structure can later be used elsewhere.

Features and advantages

- Strong and robust with no maintenance

- Modular and customized application with very high wall construction possibility

- Long life cycle – can typically last the lifetime of a building

- Fast installation. Five to eight times faster. Easy to control the construction progress

- Combinative non-messy dry construction – clean, dry and dust free work environment

- The dry cladding method is safe and it prevents the stone from falling off for years. This method allow for expansion and contraction of stone in extreme weather conditions

- Good vibration absorbing ability. Suit buildings on seismic belt

- Fast reconstruction for easy assembling and dismantling

- Filling acoustic sound insulation can enhance the sound-proof ability

- Electric wires and plumbing services etc are hidden in the wall but can be accessed easily with removable panels

- Light weight systems – 8 to 10 times lighter than conventional systems like Brick / Block work. This can reduce the overall weight and cost of the building structure

- Flexibility in terms of modifications and refurbishment in future. It is 100% reusable.

- Excellent fire resistive ability. Suit residuals and public places

- Green and recyclable product

Specifications

Providing IQUBX DWP01 modular fast installing dry wall cladding room partition system for fitting stone and tile panels of 18mm – 19mm thickness on to the existing wall surfaces. The dry wall cladding system to be made of horizontal extruded aluminium engineered sections with high bending strength 25 x 38 with provision for allen bolt fixing; base channel section for holding panels in floor with rounded skirting integrated 47 x 20; top fixing channel for individual panels to be fixed to frame work members 68 x 31; top finishing channel 39 x 40. The system may include vertical strong post members extruded aluminium sections, which can be used, if required, 50 x 50 with provision of allen bolt fixing. The system may have panels stacked vertically with joints in between of 13mm anodized section visible. The entire system, except the base frame, to be anodize / powder coat finish as per requirement. The panel surface shall be not more than 65 mm from the wall surface. The system allows for easy dismantling and re-fixing of individual panels as well as to allow services maintenance behind the cladding, if required

- BASE CHANNEL 47 X 20

- PANEL FIXING CHANNEL 68 X 31

- TOP FINISHING CHANNEL 39 X 40

- VERTICAL POST 50 X 50, 38 X 25

For more information on the products and placing orders

Call +91 9999001967, 8506074444, 7065444402

Or email at info@iqubx.com and amit@iqubx.com

Visit our site www.iqubx.com to check out more products

We wish to tie up in India and other countries for marketing these products. Please connect with me for collaborations.

Subscribe to our newsletter for latest updates!